information Center

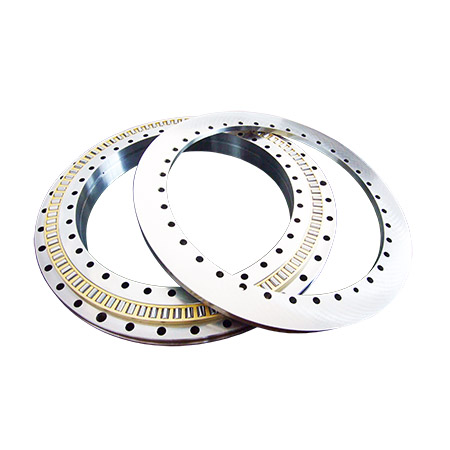

Grease for slewing bearing swing bearing

- 2022-06-29 06:40:00

Fill the track of the slewing ring with high-quality grease. The tooth meshing lubrication of the gear tooth system.Lubrication operations should be filled at least after every 100 operating hours. If the slewing ring is exposed to high humidity, significant temperature changes and high rotational speeds, the lubrication process should be more frequent!...

learn more

Common problems and solutions of slewing bearings (Part 4)

- 2022-04-28 06:26:00

Rotation of the slewing bearing is not flexible.(1) The idling of newly purchased products is not flexible.Remedy: If it can run after afterburning and there is no other abnormality, it can be used normally.(2) The operation is not flexible after installation.Solution:• Re-process the installation plane of the main engine to make the installation plane ...

learn more

Common problems and solutions of slewing bearings (Part 3)

- 2022-03-28 09:38:00

Abnormal Noise(1) The slight abnormal noise when the new product is idling will generally disappear after dozens of turns. If it does not disappear, it may be caused by slight deformation of the slewing bearing during transportation.(2) After the assembly, there is abnormal noise in the trial operation. It should be checked whether the installation surf...

learn more

Common problems and solutions of slewing bearings (Part 2)

- 2022-02-09 00:41:00

ShakeAfter the slewing bearing is loaded, its clearance is about 3-5 times that of the factory inspection (three-point inspection method), and it can continue to be used within this range.(1) The mounting bolts are loose, causing shaking during work. Immediately check all inner and outer ring mounting bolts and tighten as required.(2) The rigidity of th...

learn more

Common problems and solutions of slewing bearings (Part 1)

- 2022-01-13 04:45:00

Broken toothReasons:(1) The backlash of the large and small gears is improperly adjusted during installation.(2) Failure to adjust the meshing clearance with the pinion at the maximum position of the tooth jump as required, resulting in a stuck and broken tooth during operation.(3) The axes of the large and small gears are not parallel or the mounting b...

learn more