information Center

Application Occasions And Design Selection Characteristics Of Precision Slewing Bearings And Heavy-Duty Slewing Bearings

2023-04-12 09:49:00

The application occasions and design selection characteristics of precision slewing bearings and heavy-duty slewing bearings have the following characteristics.

1. The material is generally 42CrMo, because it has good quenching and tempering properties, so the hardness and toughness have substantial unity.

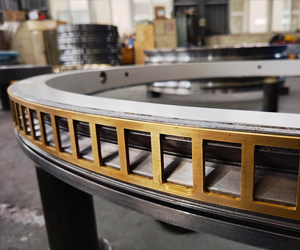

2. In order to improve the stability and reliability of the bearing, the cage adopts segmented cages and integral cages. In order to reduce noise and weight, the cage materials are nylon cages, copper cages, PA66, BASF engineering plastics, etc.

3. Improving the precision grade and process level of the bearing is mainly customized for the working conditions, among which clearance, end runout and tooth runout are the core indicators.

4. The lubrication and sealing system is the first line of defense, so the protective cover and gray baffle are specially designed.

5. In order to improve the anti-corrosion and wear-resistant coating of the bearing, it is particularly important to spray zinc, aluminum and ceramics, tungsten carbide and chrome-nickel plating.

Regarding precision slewing bearings, high-speed light-load slewing bearings, and precision measurement and control positioning and positioning bearings, the structure, cage form, and process added value must be redesigned and considered.

.jpg)

.jpg)