information Center

Slewing bearing lubrication and maintenance methods

2017-12-12 03:52:00

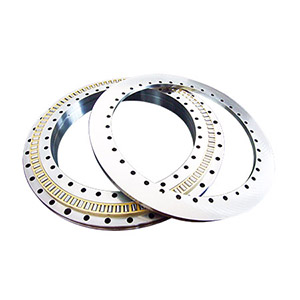

1. A small amount of No. 2 extreme pressure lithium-based lubricating grease (GB/T7324-1994) is coated on the track of the slewing bearing when it leaves the factory. When it is put into use, it should be filled with new lubricating grease according to different operating conditions.

2. The raceway of the slewing bearing should be filled with lubricating grease regularly. Generally, the ball bearing is refueled every 100 hours of operation, and the roller bearing is refueled every 50 hours. In special operating environments, such as tropical areas, high humidity, dust, large temperature differences, and continuous operations, the smoothing cycle should be shortened. It is also necessary to add new grease before and after the machine is suspended for a long time.

3.The tooth surface should be frequently cleaned of debris and coated with corresponding lubricating grease.