information Center

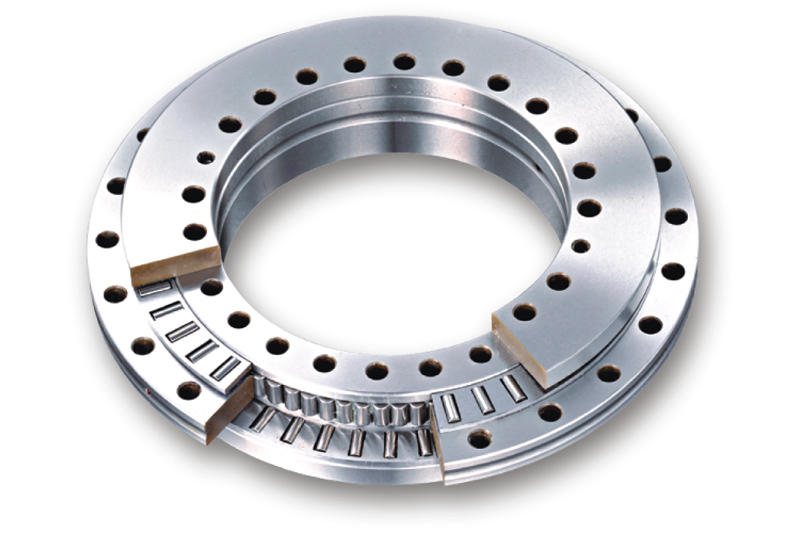

Preventive measures for rusting of slewing bearing

- 2021-09-22 08:58:00

1. Immersion methodFor small bearings, it can be soaked in anti-rust grease to reduce the chance of rusting.2, brushing methodFor some larger slewing bearings, the soaking method cannot be used, and it can be brushed. When brushing, pay attention to evenly smear on the surface of the slewing bearing, so as not to cause accumulation and leakage.3. Spr...

learn more

Precautions for loading, unloading and storage and transportation of slewing bearing

- 2021-08-12 05:01:00

1.The slewing bearing must be carefully installed and removed.2.The transportation and storage should be placed horizontally, and the storage must be placed in a dry room.3.Lifting should be done with lifting ring screws in a horizontal way, and do not collide, especially in the radial direction.4. The outer surface of the slewing bearing is coated w...

learn more

Matters needing attention when using slewing bearing

- 2020-10-16 09:44:00

1. Refill with suitable grease as needed.2. Maintain a good lubrication state and keep records. When using in dusty and humid areas, it should be lubricated at least once a week according to the specific situation.3. Sufficient preload must be maintained.4. The tooth surface of the slewing bearing should be cleaned every 8-10 working days.

learn more

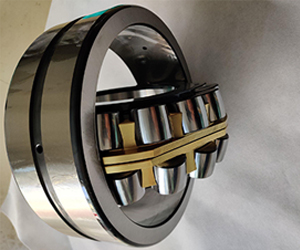

Basic requirements for spherical roller bearings used for sealing materials

- 2017-04-20 03:09:00

1. The spherical roller shaft is wear-resistant and will not corrode metal;2. Good oxygen resistance and aging resistance, durable;3. Bearings are resistant to high and low temperatures. It does not synthesize and soften at high temperatures and does not harden at low temperatures;4. The spherical roller shaft is compatible with the working medium, w...

learn more

The importance of bearing working clearance

- 2017-03-09 06:13:00

Working clearance is an important quality index of rolling bearings, and it is also an important parameter in bearing applications. In actual use, the working clearance of the bearing will affect the load distribution, vibration, noise, friction torque and life of the bearing. Especially in the combined reducer running at high speed, once the working...

learn more